You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flexacopter ---The Making Of---

- Thread starter holco

- Start date

holco

Member

Hi There dear followers,

I get many questions about what the changes are on the V2 version.

We changed some parts with PA 2200 nylon carefully processed using Selective Laser Sintering, this material is very strong and durable and produced on the best High-End 3D printing machines available, the advantage is that we can use less parts on some places and other parts will be lighter then the GFK/POM parts used on de V1, also this new parts will be more crash resistant because its virtually unbreakable, all the PA 2200 parts will be produced in the color RED because we think it looks nicer than the standard white and its a good looking combination with the black carbon

More info about the material PA2200 info

Witch parts are changed,

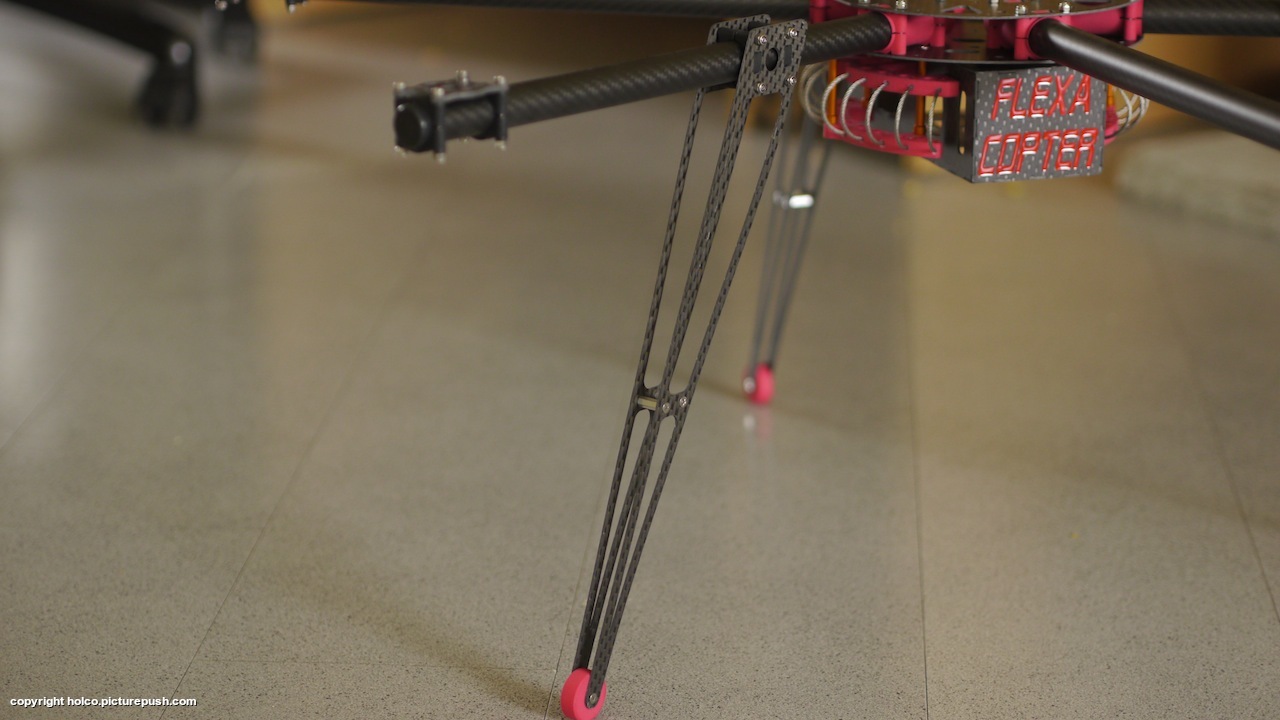

POM round feet's

gfk wiredamper supports

clamps on the frame and gfk plug system

gfk plugs on the arms

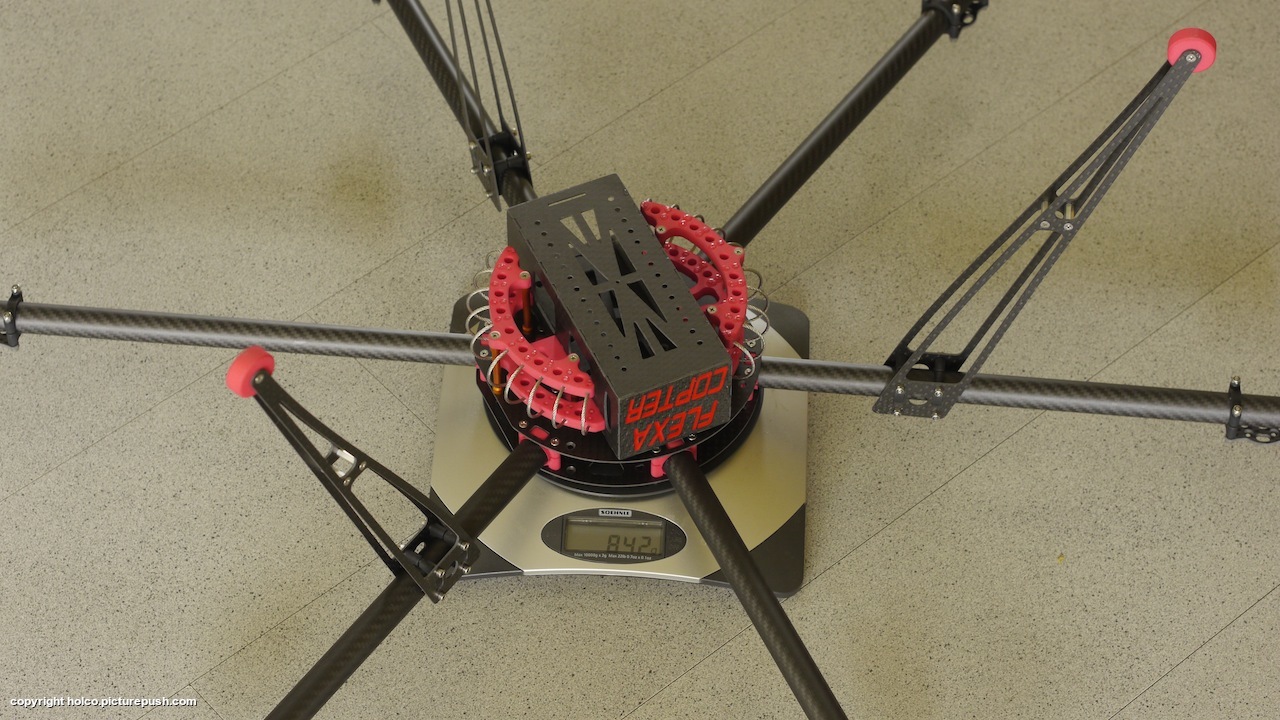

weight advantage +/- 125 gram (10% on the full options kit)

Some renders of the new plug system,

Greetings,

Mario/Pieter

I get many questions about what the changes are on the V2 version.

We changed some parts with PA 2200 nylon carefully processed using Selective Laser Sintering, this material is very strong and durable and produced on the best High-End 3D printing machines available, the advantage is that we can use less parts on some places and other parts will be lighter then the GFK/POM parts used on de V1, also this new parts will be more crash resistant because its virtually unbreakable, all the PA 2200 parts will be produced in the color RED because we think it looks nicer than the standard white and its a good looking combination with the black carbon

More info about the material PA2200 info

Witch parts are changed,

POM round feet's

gfk wiredamper supports

clamps on the frame and gfk plug system

gfk plugs on the arms

weight advantage +/- 125 gram (10% on the full options kit)

Some renders of the new plug system,

Greetings,

Mario/Pieter

holco

Member

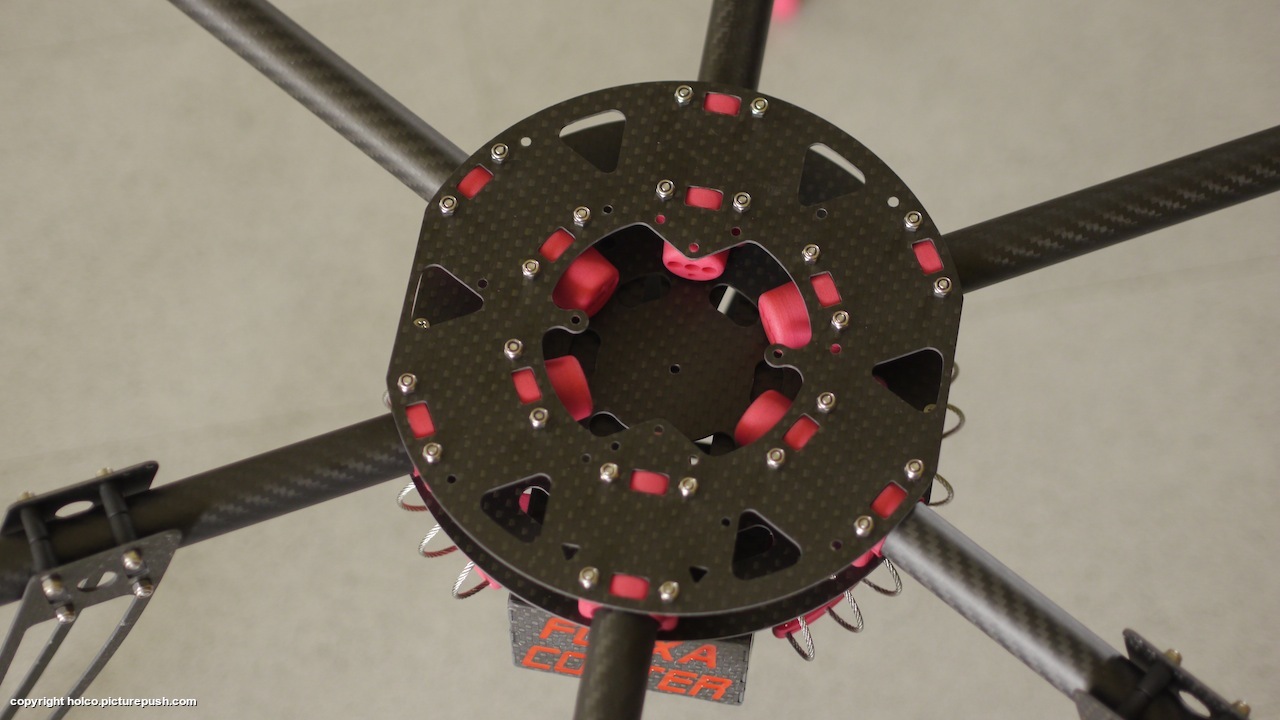

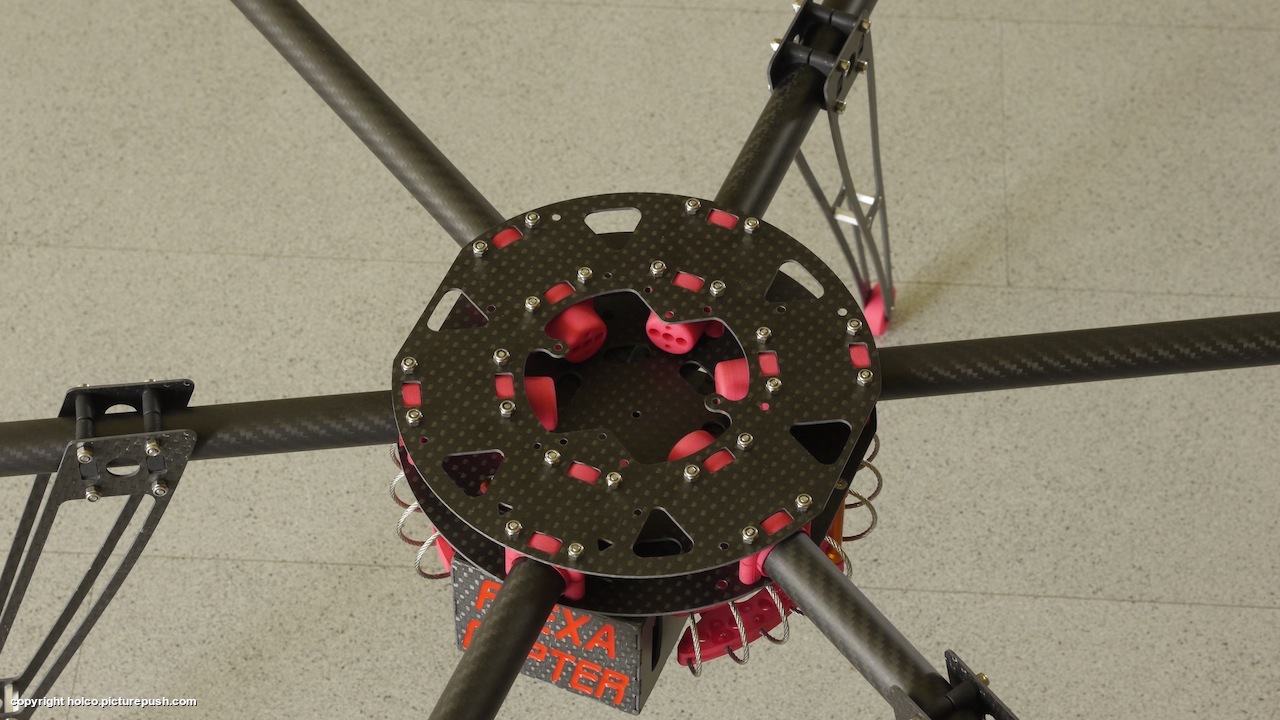

The new V2 frame,

New arm mounting system with intergradet plug system.

MK and DJI mounting holes intergradet in top plate.

Two arrows for flight direction in top and bottom plate.

The 6 screws from the ESC standoff's now attainable thru bottom plate.

Bigger center hole in top plate.

Mounting holes for the dome fixing system now also in top plate for higher mounting position.

More holes in bottom plate for easy cabling to gimbal.

Lighter without loosing strength.

New arm mounting system with intergradet plug system.

MK and DJI mounting holes intergradet in top plate.

Two arrows for flight direction in top and bottom plate.

The 6 screws from the ESC standoff's now attainable thru bottom plate.

Bigger center hole in top plate.

Mounting holes for the dome fixing system now also in top plate for higher mounting position.

More holes in bottom plate for easy cabling to gimbal.

Lighter without loosing strength.

Last edited by a moderator:

holco

Member

Thanks Gunter

Carbon booms are 20mm, and yes indeed you loosen two loc-nuts and take the arm out without worries about the wiring.

Greetings,

Mario

Carbon booms are 20mm, and yes indeed you loosen two loc-nuts and take the arm out without worries about the wiring.

Greetings,

Mario

Wow, that looks like a very neat solution. What diameter booms are you using? I assume you can then simply unplug a boom to take it apart?

Gunter.

holco

Member

Thanks Boris,

Indeed the V12 was a special for a German guy, standard is 3 motor connections + 2 small light/buzzer connectors per arm.

Greetings,

Mario

;

Indeed the V12 was a special for a German guy, standard is 3 motor connections + 2 small light/buzzer connectors per arm.

Greetings,

Mario

;

Ah okay you are making one special V12 version.

holco

Member

holco

Member

Shoot a test video without the active stabilisation from the pillock, zo the tilt and roll axis from the mount where locked by the mechanical resistance from the servos without power.

The only thing between the flexacopter and the mount are the wire dampers.

The video is stabilised with Final Cut Pro

The only thing between the flexacopter and the mount are the wire dampers.

The video is stabilised with Final Cut Pro

Last edited by a moderator:

holco

Member

Today I made a remote shutter control with Pieter so that we can make pictures also.

First shoot on 120m in burst mode 430 photos total in one flight.

Some samples including a link to the original file in 4976x2800

http://holco.picturepush.com/showformat.php?format=img&image=7973930

http://holco.picturepush.com/showformat.php?format=img&image=7973923

http://holco.picturepush.com/showformat.php?format=img&image=7973918

http://holco.picturepush.com/showformat.php?format=img&image=7973908

http://holco.picturepush.com/showformat.php?format=img&image=7973901

http://holco.picturepush.com/showformat.php?format=img&image=7973894

First shoot on 120m in burst mode 430 photos total in one flight.

Some samples including a link to the original file in 4976x2800

http://holco.picturepush.com/showformat.php?format=img&image=7973930

http://holco.picturepush.com/showformat.php?format=img&image=7973923

http://holco.picturepush.com/showformat.php?format=img&image=7973918

http://holco.picturepush.com/showformat.php?format=img&image=7973908

http://holco.picturepush.com/showformat.php?format=img&image=7973901

http://holco.picturepush.com/showformat.php?format=img&image=7973894

holco

Member

holco

Member

Thanks jrlederer

You can contact us via, info@flexacopter.com

Greetings,

Mario

You can contact us via, info@flexacopter.com

Greetings,

Mario

So, where to Greg one of these cool designs, holco? I would like to test out your labor of love and obtain similar results. Looks great! Keep it up

holco

Member

Because I was not happy with the low gear ratio of the tilt axel from the AV-130 mount Pieter created a new 20T servo pulley from carbon for me, the standard pulley is 32T whats give a gear ratio of 2,5:1, now I have a ratio of 4:1 what almost doubles the resolution

The result is that there is more tranquility on the tilt axel.

Test shot with the 4:1 ratio,

The result is that there is more tranquility on the tilt axel.

Test shot with the 4:1 ratio,

Last edited by a moderator: