Toymaker

Crashologist

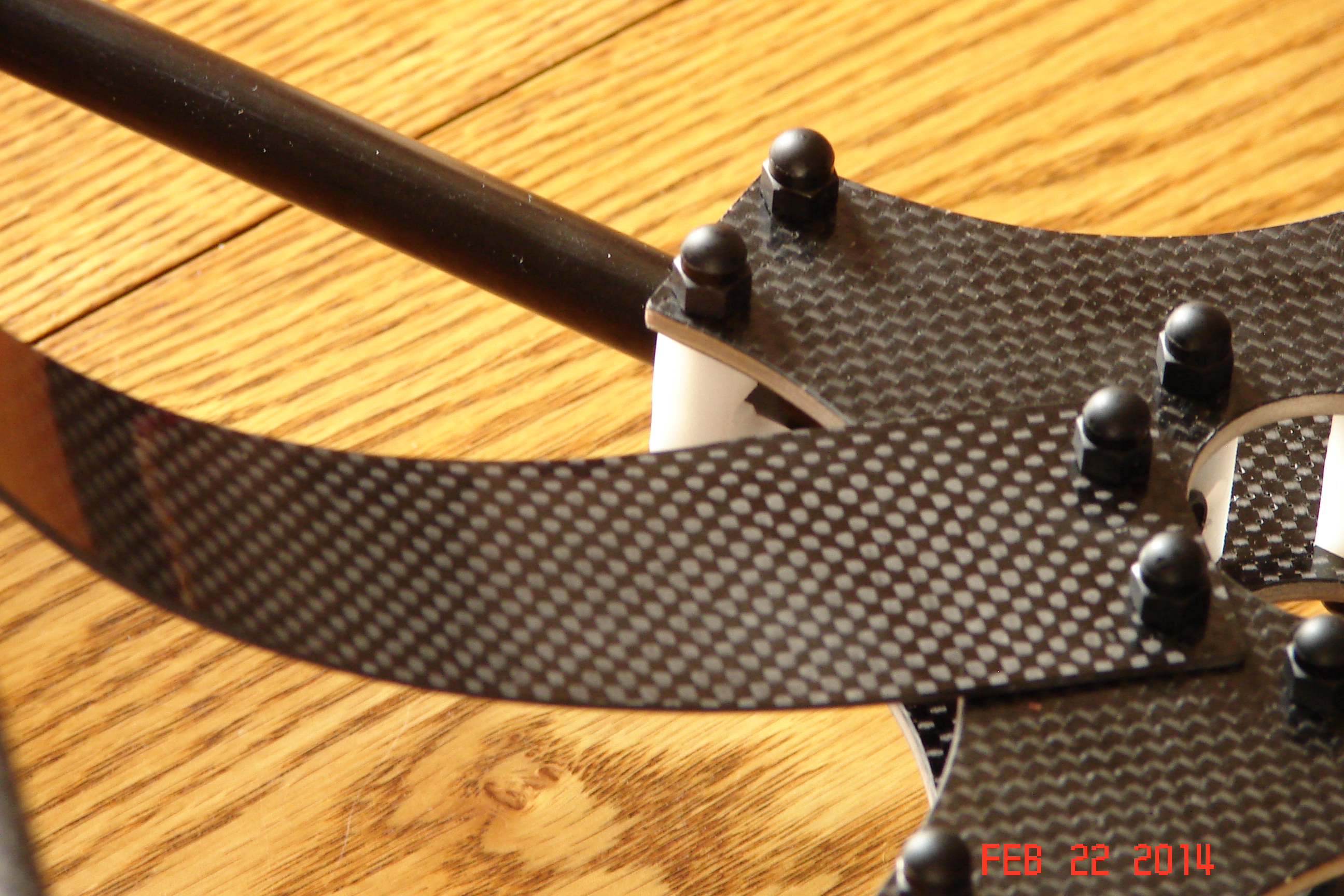

I'm new to the forum but I have building and designing stuff for a while, about 35 years. This is my first attempt at a Quadrotor. After researching frame / motor/ prop sizes I decided I'd give it a go. I started out designing it in Autocad on my laptop while watching tv one night. This turned into several nights and more and more detail.I've been trying to keep it light and strong. Normally those are polar opposites, so I've been working on using light weight and strong materials. I also have access to a machine shop at work so I can work on stuff at lunch or after work. So far things have been coming together nicely. When it's done it will be a 500mm quad X.

View attachment 16278

View attachment 16278