Efliernz

Pete

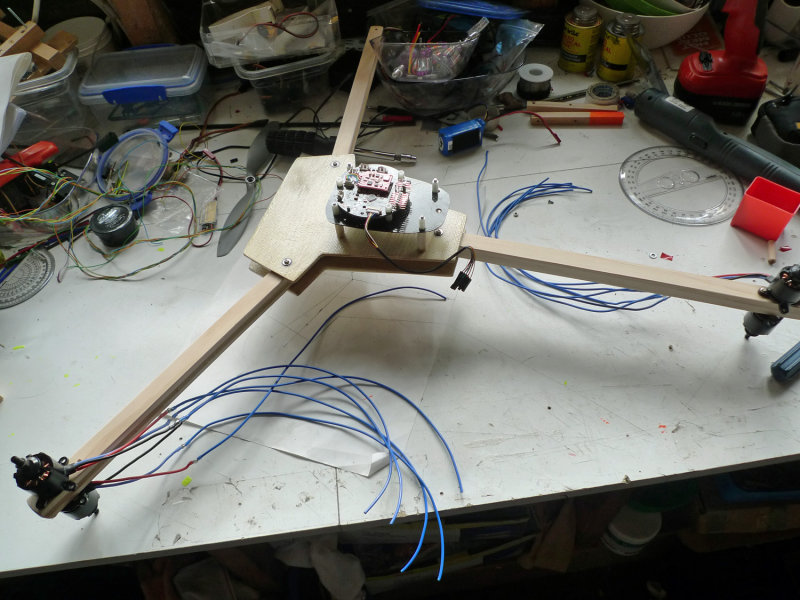

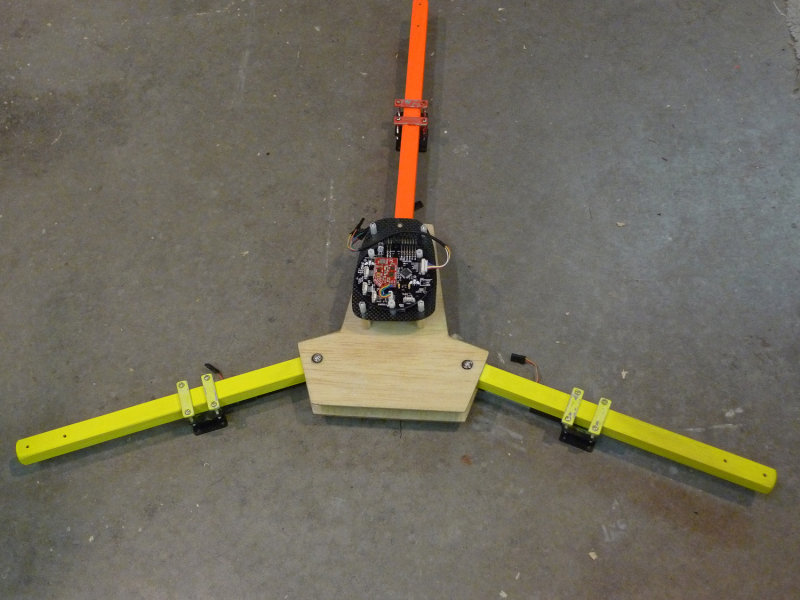

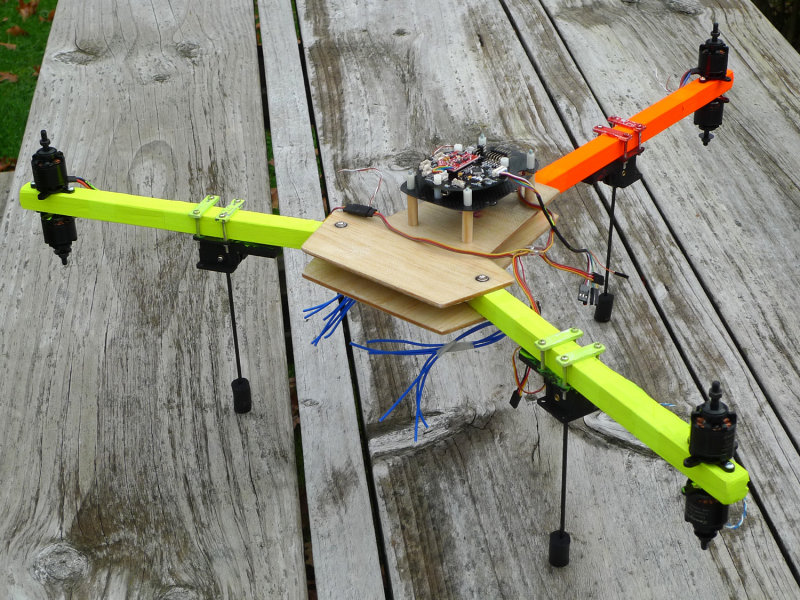

I built a wood and Hobbyking carbon sheet folding Y6 using RCT2836/11 750Kv motors and it went really well...

... so well that a club mate wanted it and bought it. Time to design my "good Y6"

I started with ordering Sunnysky X2212 980Kv motors and 18A Plush esc's.

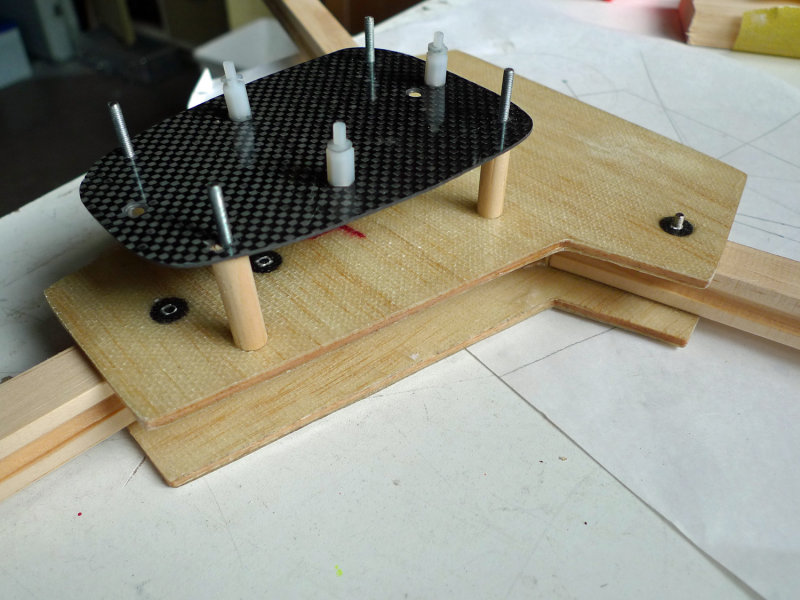

I was going to use retracts again as I want it to fold and fit in a spare tripod bag for when I go tramping and feel the need to fly over a waterfall...

20 minutes on Visio and I had the basic layout sorted.

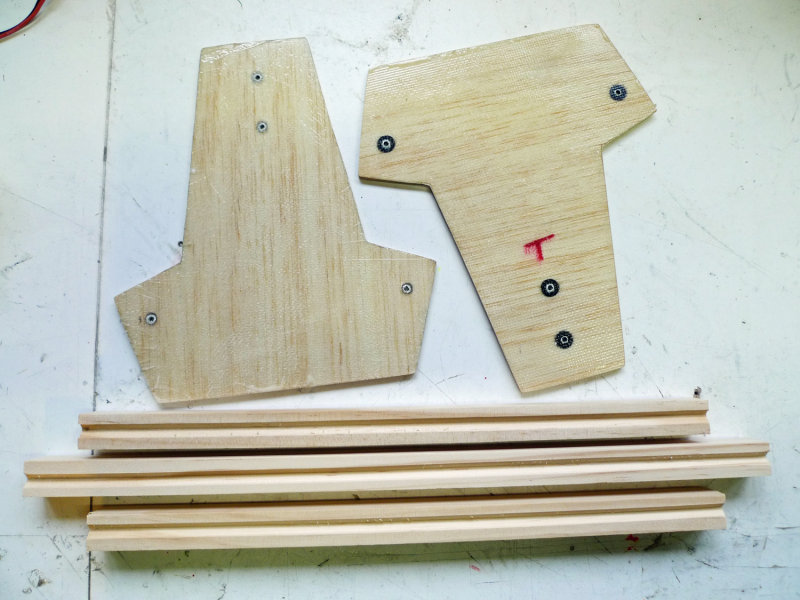

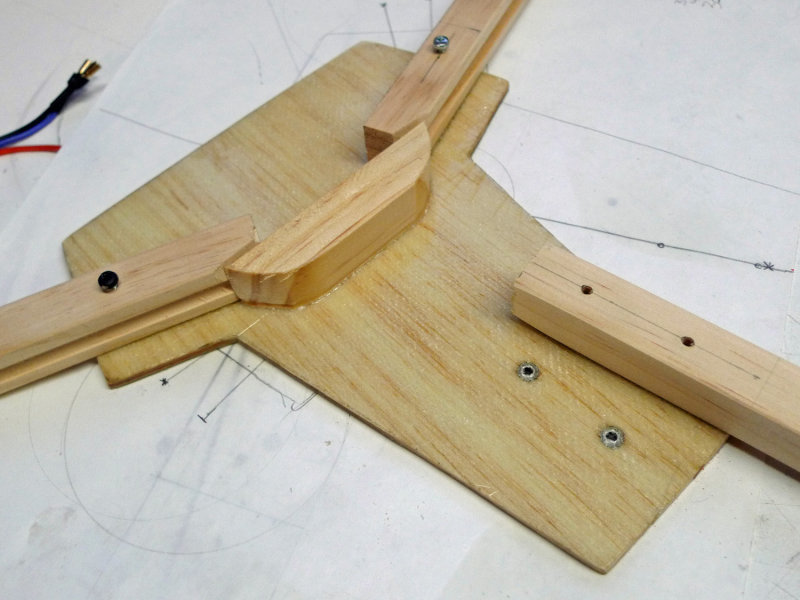

I didn't have enough carbon lying around so I tried (for the first time) a fibreglass lamination using balsa as the core. Nice and light.

3 ply lamination using 0.8mm (1/32) top and bottom with 1.6mm (1/16) in the middle. This was epoxied and stuck between a plank and a 5mm glass sheet with 40Kg of batteries on top.

I had worked out where the hard points would be for the arm-securing bolts. I found some tapered washers that were exactly the same width as the balsa.

Layup time - two layers of 200g cloth, X-orientation against the balsa, + orientation on top. Underneath and on top were done at the same time. I used clingfilm/lunchwrap to stop the epoxy sticking to the base bench and the glass. 40Kg of batteries overnight

Pete

... so well that a club mate wanted it and bought it. Time to design my "good Y6"

I started with ordering Sunnysky X2212 980Kv motors and 18A Plush esc's.

I was going to use retracts again as I want it to fold and fit in a spare tripod bag for when I go tramping and feel the need to fly over a waterfall...

20 minutes on Visio and I had the basic layout sorted.

I didn't have enough carbon lying around so I tried (for the first time) a fibreglass lamination using balsa as the core. Nice and light.

3 ply lamination using 0.8mm (1/32) top and bottom with 1.6mm (1/16) in the middle. This was epoxied and stuck between a plank and a 5mm glass sheet with 40Kg of batteries on top.

I had worked out where the hard points would be for the arm-securing bolts. I found some tapered washers that were exactly the same width as the balsa.

Layup time - two layers of 200g cloth, X-orientation against the balsa, + orientation on top. Underneath and on top were done at the same time. I used clingfilm/lunchwrap to stop the epoxy sticking to the base bench and the glass. 40Kg of batteries overnight

Pete

Last edited by a moderator: