GearheadMachine

Member

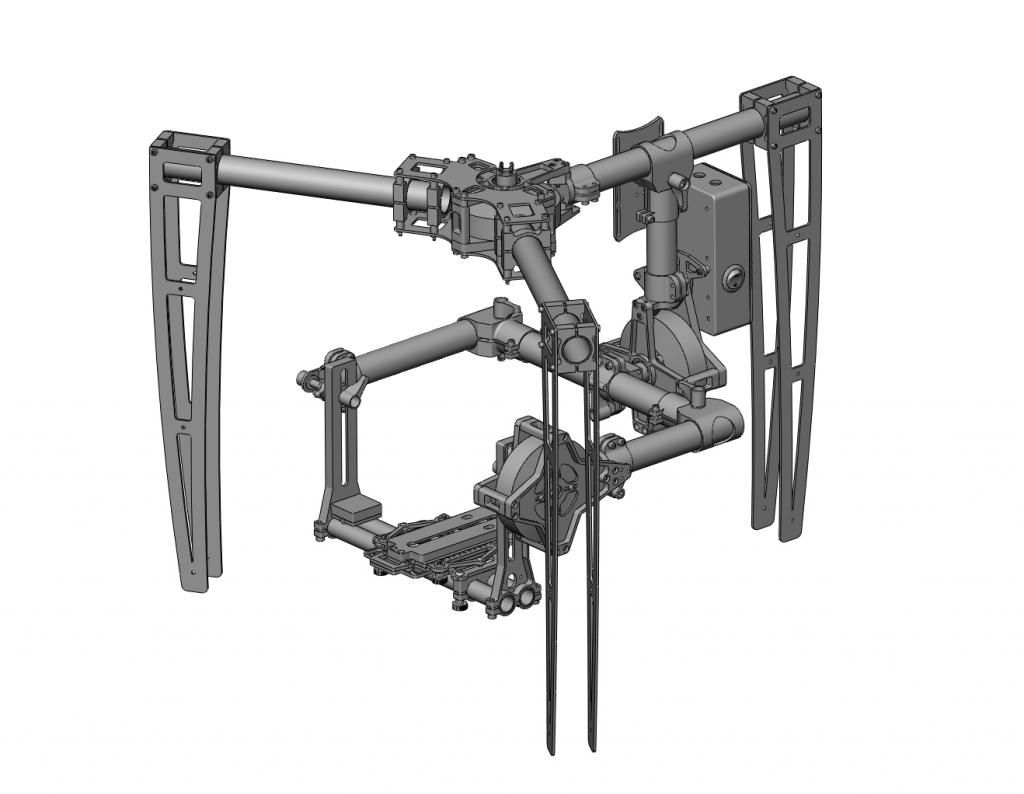

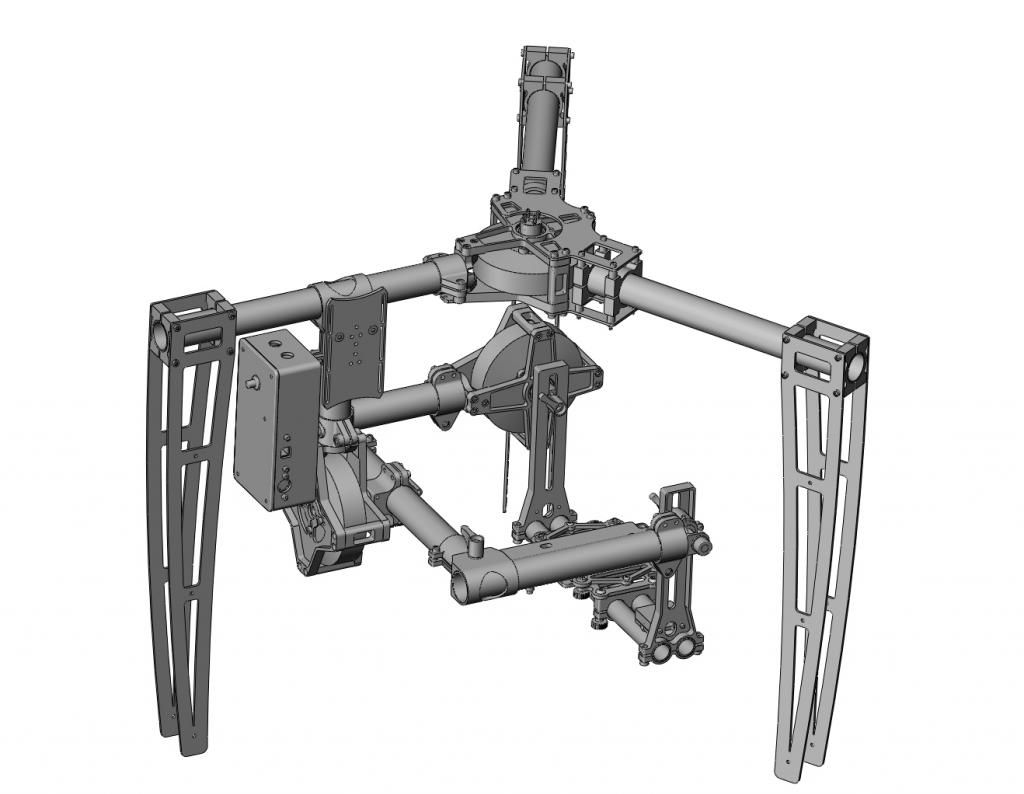

I have for sale brand new DIY Brushless Gimbal Motor Cages. These are for use on a DIY gimbal project to hold larger cameras such as the Canon 5D, RED, Sony FS700 etc. The name of our company is Gearhead Machineworks (a division of Gearhead Flicks LLC). You can see our video services website at www.gearheadflicks.com

This new division of our company is designing and building revolutionary and unique products for the DIY gimbal and multirotor market. These motor cages are the first product we have released but we have many more in the works, soon to be released. These motor cages have been under design and development for a good year now and are better than anything else available to the DIY builder currently. We have an ad to these cages on our ebay store but if you buy one from us on this forum we will take off 5% from our sale price of $299. So that is $285 (AND) we will offer free shipping too! These cages come with a return warranty within 30 days if you are not satisfied. Here is all the info on these:

Gearhead Machineworks W.A.S.P. 12 Motor Cage System

There is a revolution going on right now in camera stabilization systems. Brushless gimbal technology is taking over. With the right system, simply amazing performance is possible. Unfortunately, full systems capable of delivering quality footage cost exorbitant amounts of money. But, are they really worth these lofty prices? At Gearhead Machineworks our goal is to bring you the best products for your build at a fraction of the cost. We sell parts and assemblies which allow you to build up your own high end camera stabilization rig. We offer premium products for the DIY market. We thoroughly test our designs in our own gimbal systems. During design and development our engineering team communicates directly with our in house video crew. Each new design is handed to the video crew for testing. Field testing is performed and feedback communicated back to our engineers. This trial by fire approach to engineering results in unparalleled quality and performance for a price you can afford. We have the best designs on the market for your DIY project.

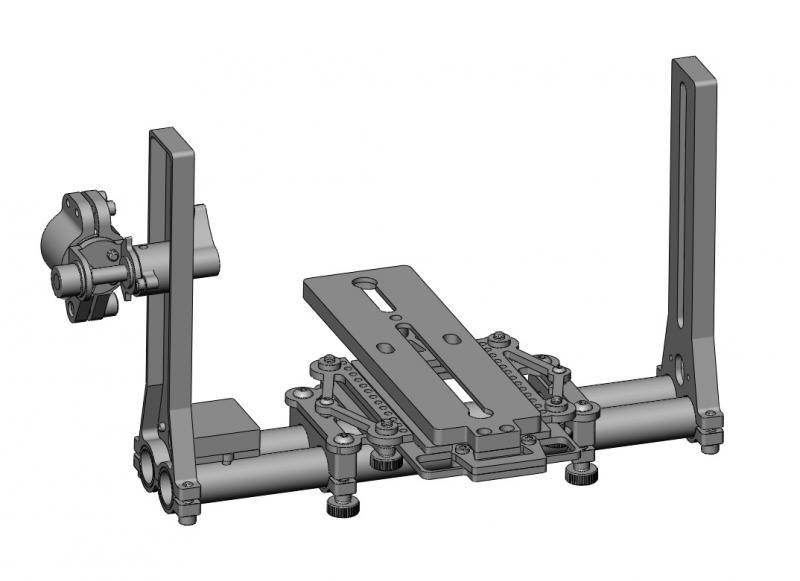

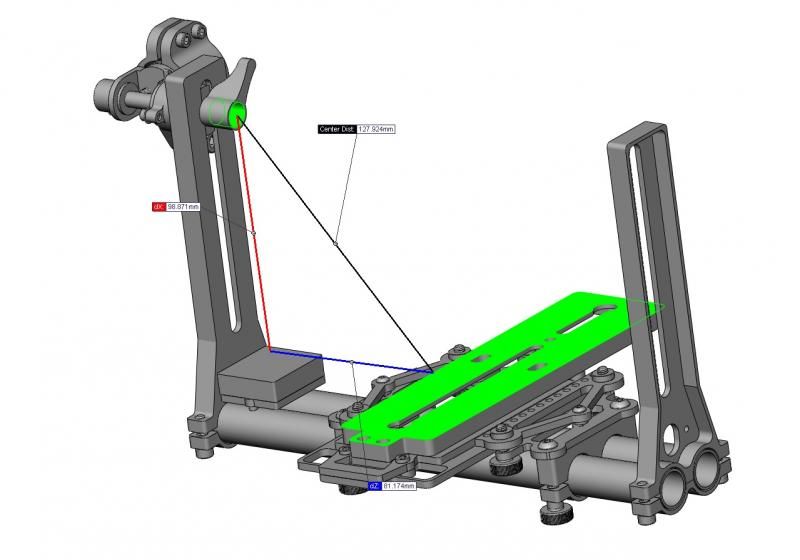

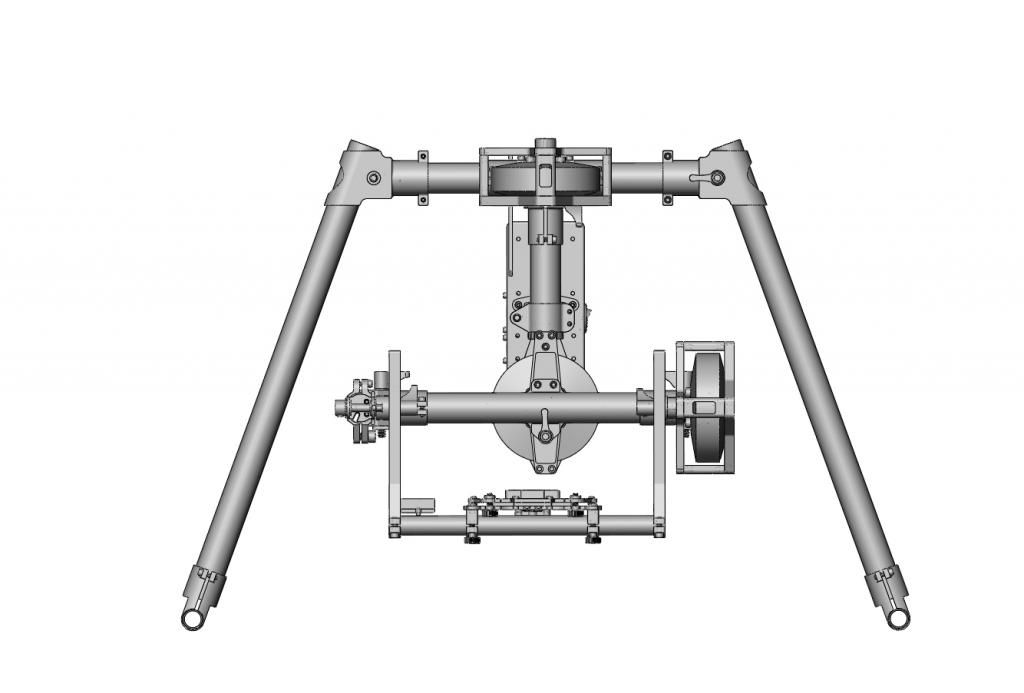

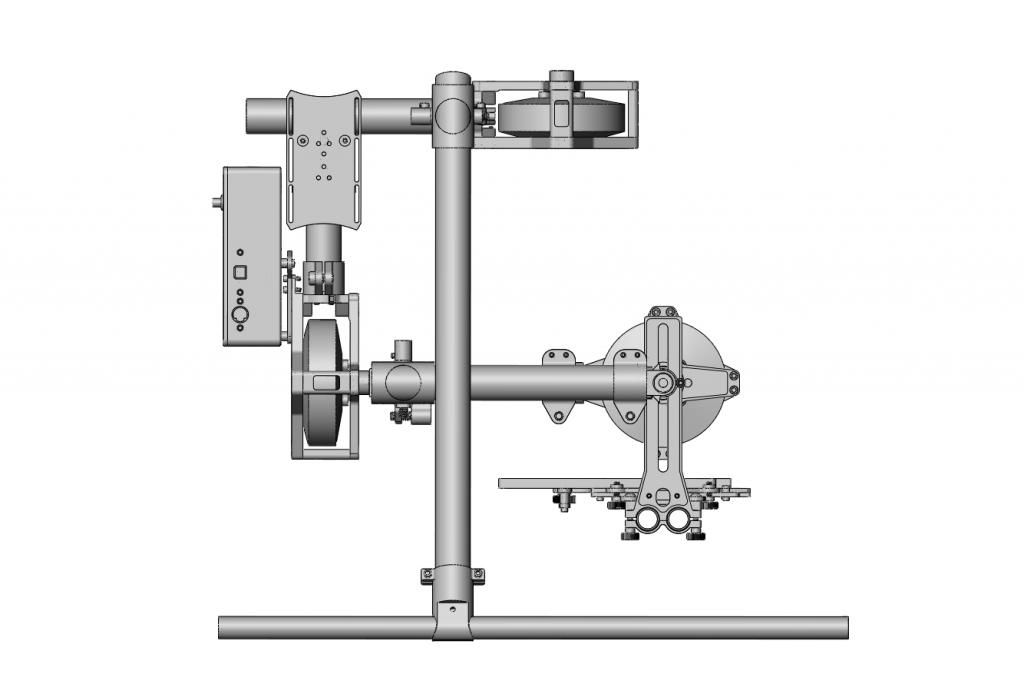

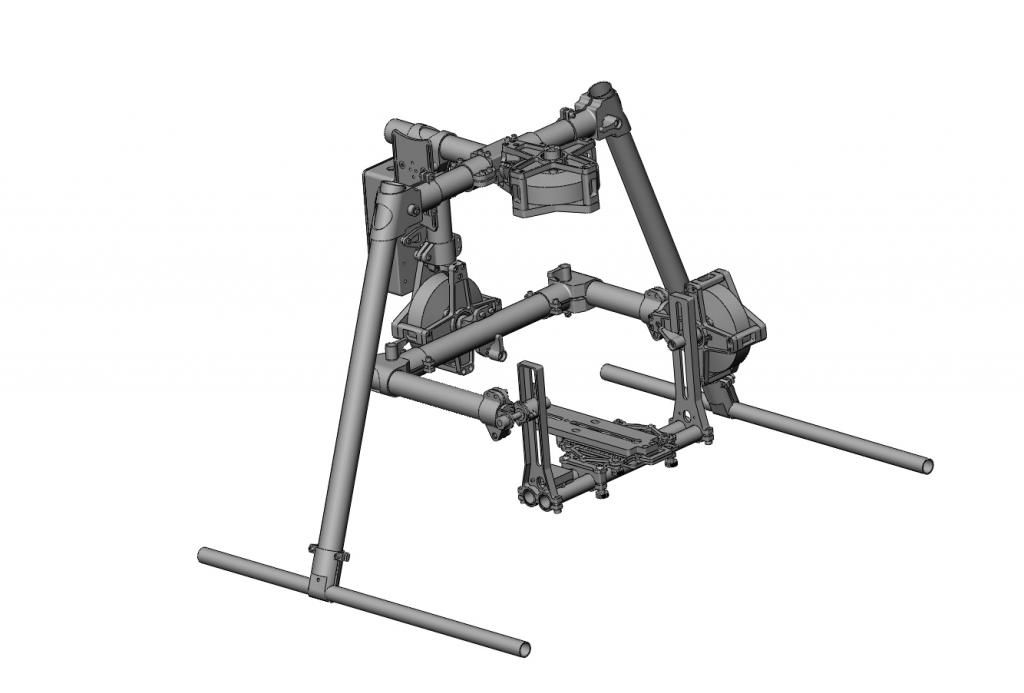

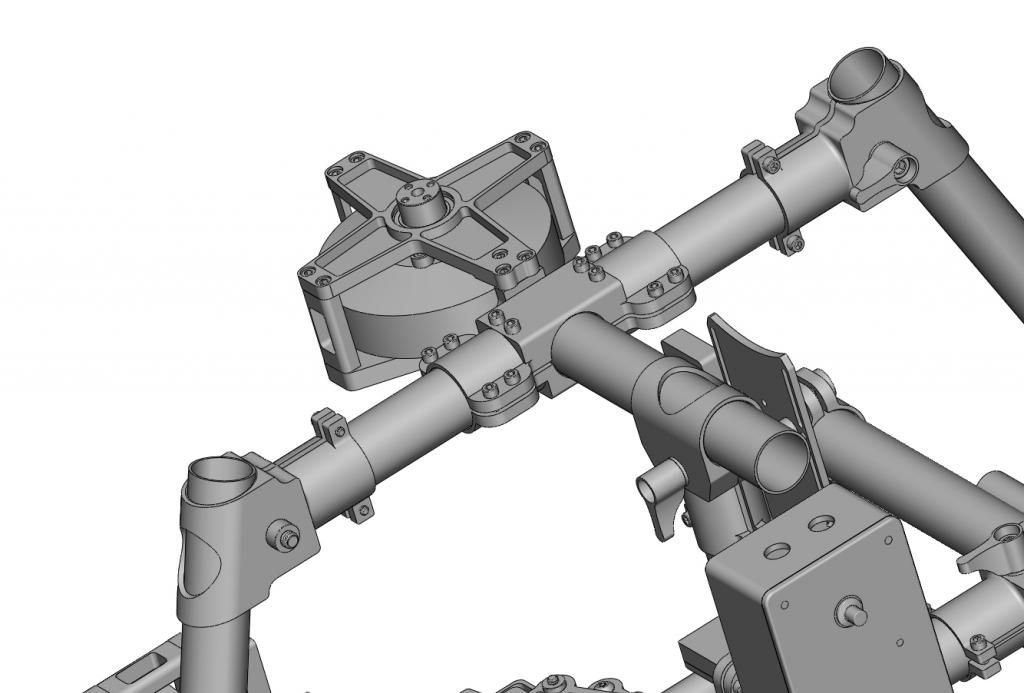

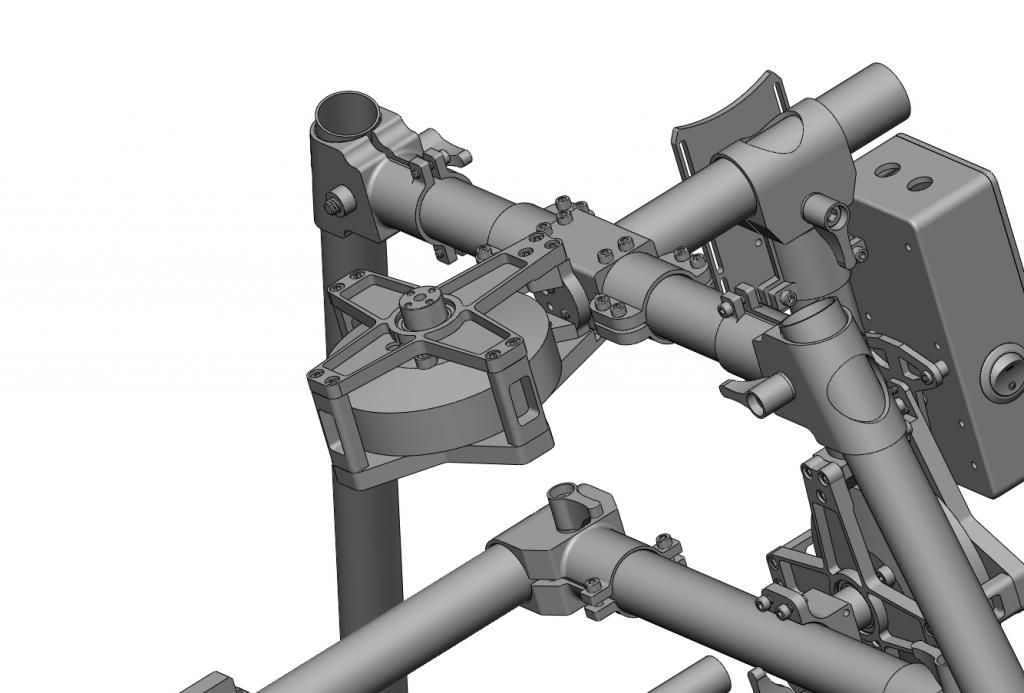

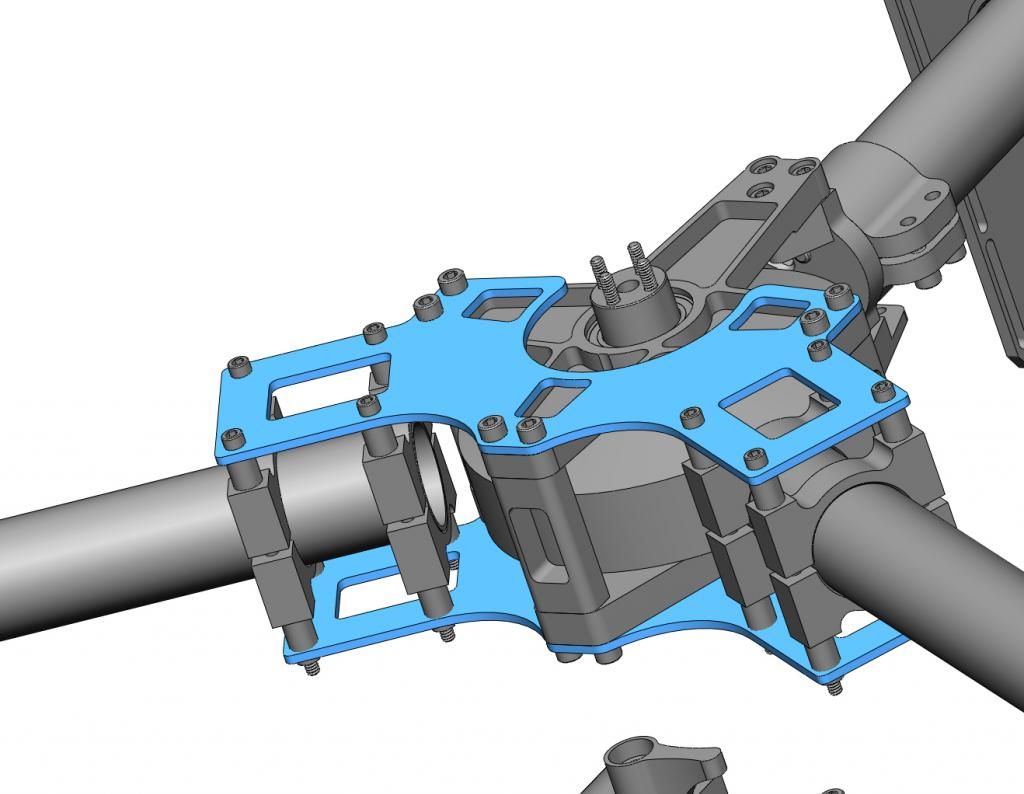

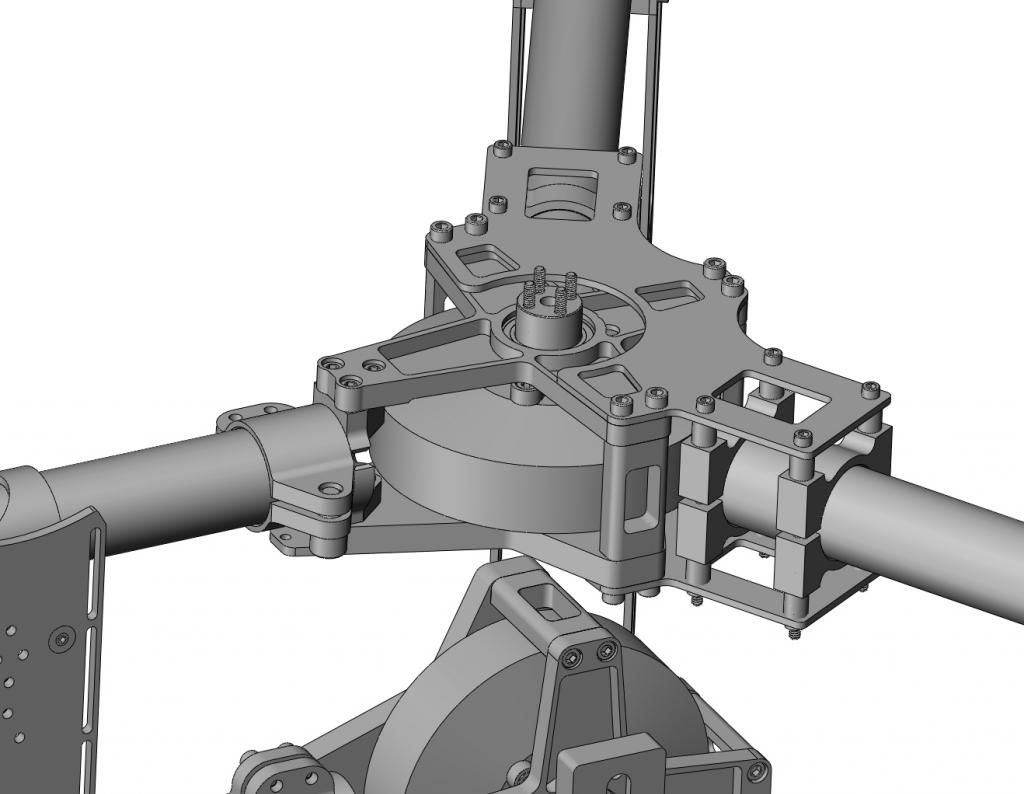

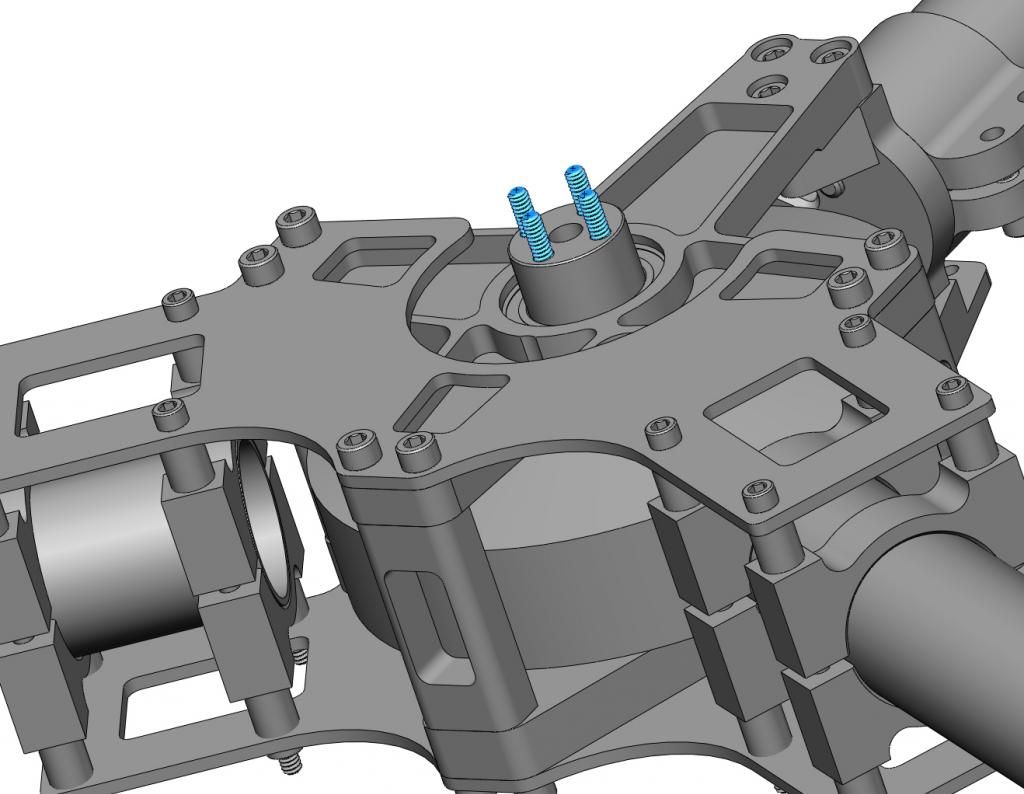

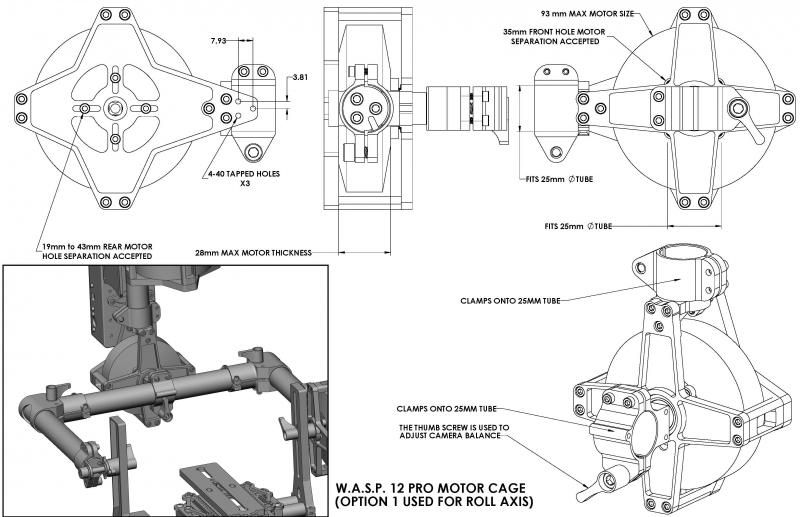

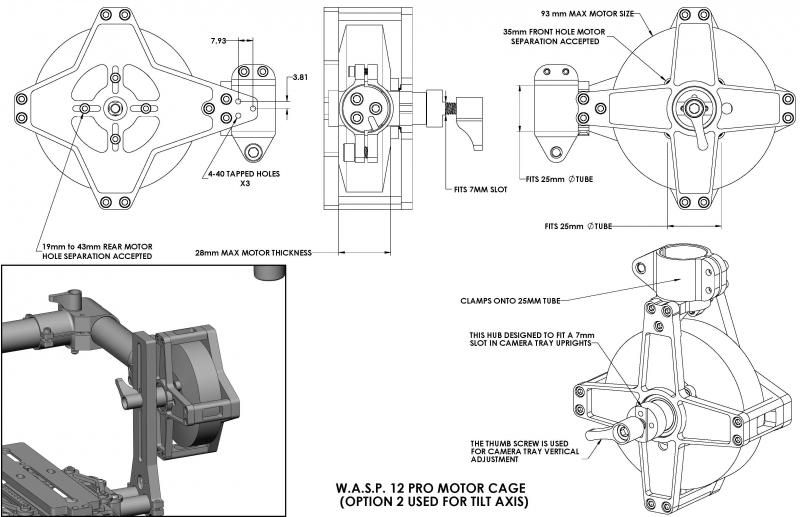

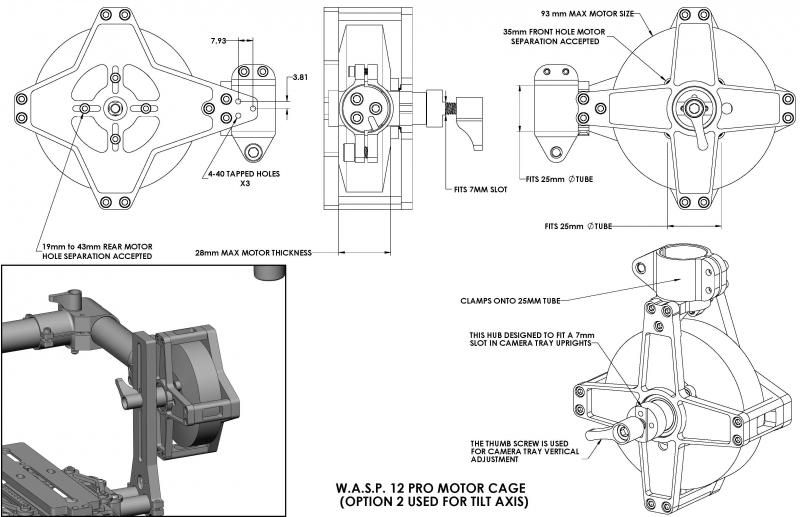

The W.A.S.P. 12 Motor Cage System is the same system we use in our gimbals. It has been through multiple design revisions and months of testing. The centerpiece of this system is an innovative outboard bearing support and super rigid aluminum motor cage design. The purpose is to eliminate flex under load and remove radial runout on the motor’s axis, commonly referred to as “slop”. Machine tolerances used in the mating parts are very tight and the structure itself is very rigid. These machine design characteristics are imperative to produce super smooth video, especially with heavy loads seen using 10-12 LB cameras. This motor support system mounts up to 25mm diameter tube. It is designed to house larger brushless motors. It accepts a number of different motor types. The motor cage has a max camera carry capacity of 12 LBS. The same motor mount system can be used on Pan, Roll, and Tilt axes by selecting which option fits your needs. Please check out our video services website too! Google "Gearheadflicks" to find our website.

W.A.S.P. 12 Motor Cage Feature List:

Technical Specifications:

This new division of our company is designing and building revolutionary and unique products for the DIY gimbal and multirotor market. These motor cages are the first product we have released but we have many more in the works, soon to be released. These motor cages have been under design and development for a good year now and are better than anything else available to the DIY builder currently. We have an ad to these cages on our ebay store but if you buy one from us on this forum we will take off 5% from our sale price of $299. So that is $285 (AND) we will offer free shipping too! These cages come with a return warranty within 30 days if you are not satisfied. Here is all the info on these:

Gearhead Machineworks W.A.S.P. 12 Motor Cage System

There is a revolution going on right now in camera stabilization systems. Brushless gimbal technology is taking over. With the right system, simply amazing performance is possible. Unfortunately, full systems capable of delivering quality footage cost exorbitant amounts of money. But, are they really worth these lofty prices? At Gearhead Machineworks our goal is to bring you the best products for your build at a fraction of the cost. We sell parts and assemblies which allow you to build up your own high end camera stabilization rig. We offer premium products for the DIY market. We thoroughly test our designs in our own gimbal systems. During design and development our engineering team communicates directly with our in house video crew. Each new design is handed to the video crew for testing. Field testing is performed and feedback communicated back to our engineers. This trial by fire approach to engineering results in unparalleled quality and performance for a price you can afford. We have the best designs on the market for your DIY project.

The W.A.S.P. 12 Motor Cage System is the same system we use in our gimbals. It has been through multiple design revisions and months of testing. The centerpiece of this system is an innovative outboard bearing support and super rigid aluminum motor cage design. The purpose is to eliminate flex under load and remove radial runout on the motor’s axis, commonly referred to as “slop”. Machine tolerances used in the mating parts are very tight and the structure itself is very rigid. These machine design characteristics are imperative to produce super smooth video, especially with heavy loads seen using 10-12 LB cameras. This motor support system mounts up to 25mm diameter tube. It is designed to house larger brushless motors. It accepts a number of different motor types. The motor cage has a max camera carry capacity of 12 LBS. The same motor mount system can be used on Pan, Roll, and Tilt axes by selecting which option fits your needs. Please check out our video services website too! Google "Gearheadflicks" to find our website.

W.A.S.P. 12 Motor Cage Feature List:

- Made in the USA

- Fit, finish, and overall build quality is outstanding

- Super rigid CNC aluminum cage construction. Aluminum is much more rigid than carbon fiber in torsion and bending experienced by camera gimbals

- Light weight

- Unique design giving your rig a PRO look and PRO performance

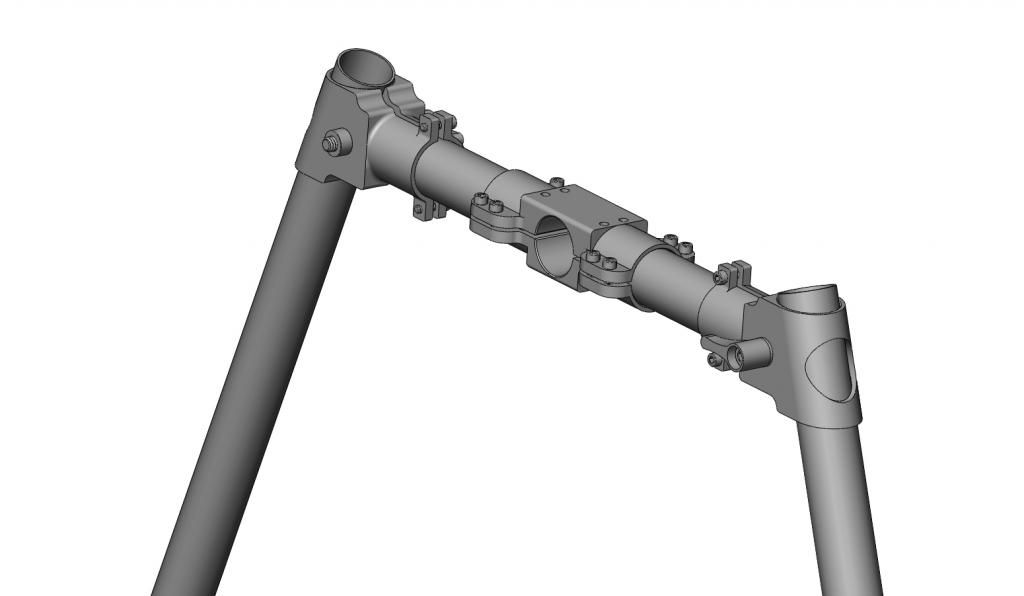

- Designed to mate quickly and easily to 25mm diameter carbon fiber tube

- Innovative external bearing support keeps axis completely slop free

- Easily install motor of your choice. Designed to fit a variety of large brushless gimbal motors (motor not included)

- Includes a slot for passing the motor wires through the carbon fiber tube, hidden from view

- Different options are available to fit your particular gimbal build configuration

- Tapped holes x 3 located on the rear of the motor mount for affixing things, such as a controller board box or battery tray

- Tool free single point balance adjustment thumb screw

- High quality matte black anodized finish

- All fasteners made of stainless steel for ultimate longevity and corrosion resistance

Technical Specifications:

- Fits the following motors: iPower GBM8028-90T, iPower GBM8017-120T, T-motor GB85-1, Rctimer GBM8108 (New motors are coming out all the time. Contact us if you want to know if a motor not listed here will fit).

- Motor rear mount hole requirement: 19mm - 43mm hole separation, 3mm screws x 4

- Motor front mount hole requirement: 35mm hole separation, 3mm screws x 4

- Motor Thickness (Depth) requirement: 26mm minimum to 28mm maximum with included hardware (thinner motors can be used with additional motor mount spacers)

- Color: Black Anodized CNC Aluminum

- Weight capacity: 12 LB Max Camera Weight

Last edited by a moderator: